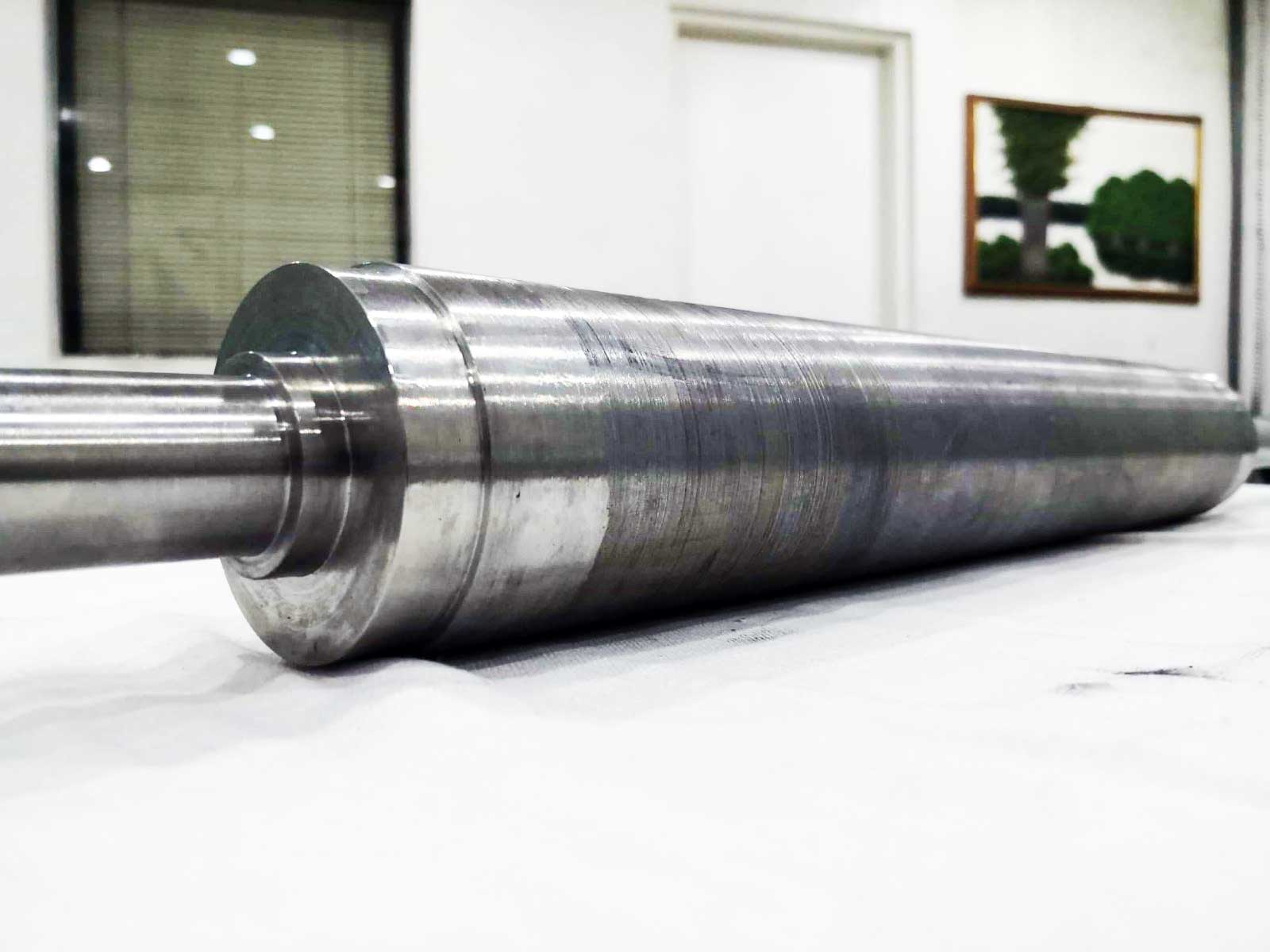

Roller Core Fabrication and Preparation: The cylinder or hollow tube is formed through sheet rolling and welding. This can be done by the rubber roller manufacturer or by a separate plant that supplies steel tubes. The ends of this tube can be machined to receive bearings. If required, flanges or support discs are cut that are sized to fit inside the cylinder. A shaft is fabricated by turning a metal stock in a lathe machine producing a cylindrical core. This shaft can either be welded to the flanges as stated above, or be slid into the bearings on each end of the tube. All dimensions must be accurate to attain the required diameter, roundness, and balance of the roller. The flanges are then welded to the ends of the cylinder together with the shaft. After fabrication, the roller core is subjected to secondary processes such as blasting and cleaning to remove any traces of corrosion and contaminants on its surface. (https://www.iqsdirectory.com/articles/rubber-roller.html)